The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

Did a little welding yesterday.

Just some 48mm OD water pipe.

Used a cheap welding mask that looks identical to the one I had 50 yrs ago.

Used a stick welder with GP rods.

That was with a cheap Chinese electronic welder I paid $169 delivered for.

That welding machine is actually quite brilliant, unlike the welder.

Stick welding I've decided gives at least a consistent weld.

And consistent is a good as I can hope for these days.

Not so easy on thin stuff or Ali etc.

Just recently I watched a friend build up a new lug on a cast iron engine barrel using a TiG.

Impressive.

It's for a 1000cc Vtwin Royal Enfield from 1926.

I did a similar repair on my 14" cast iron frypan 50 yrs ago using a stick weld and nickel rods.

Still using that pan.

My old MIG welders are not flash now but still work OK for the most part.

The one I bought new 20yrs ago has issues at low wire speed settings and the one I got almost new old stock still in its box at 25yrs old is only small so ok on small stuff.

Both gaseless for convenience.

I may at some point look into a MIG suitable for Ali up to 3 or 4mm.

Set up for my TIG I found to be a major challenge.

It is more capable than the operator who takes a few days to get up to speed.

Still can't leave it alone though.

Posted by: @ben-franklin@scott-h you are off to a great start, picking the skills back up.

Lovely Miller helmet. I cheaped out and did HF's best Vulcan helmet and am still really enjoying the electronics. What an improvement from the old days!

Glad you like the Primeweld Mig. I sure enjoy their TIG unit, and suspect that the MIG will be a future addition to the shop, should I start another build.

Will be fun to follow your build!

Some pretty great reviews on Primeweld's TIG units as well. 😎 I thought it might be easier to regain old skills with MIG, versus trying to learn TIG skills.

Tech has definitely move forward on all fronts. This helmet is a Lincoln Electric model 3350. Although Miller has a pretty similar unit. From the reviews a person would do well either way. If my eyes were better, and/or I was welding daily a less expensive helmet would probably be okay.

Took the weekend off. It will be interesting to see if I've retained anything from last week. 🤓 Getting anxious to start vertical weld practice. Once that skill is remastered, it will be time to start work on project #1, the trailer lighting mods.

Hold my keyboard and watch this! 🙃

Did a little research today.

According to an article I read.

There's at least 90 different welding processes or types of welding.

And that was an older article.

They quoted things I've not heard of.

And the Egyptians dabbled with soldering thousands of years ago.

Please resume normal programming.

Posted by: @brstrDid a little research today.

According to an article I read.

There's at least 90 different welding processes or types of welding.

And that was an older article.

They quoted things I've not heard of.

And the Egyptians dabbled with soldering thousands of years ago.

Please resume normal programming.

Was reading The Procedure handbook of Welding. Turns out they've been working on Laser Welding since the '60s. Here I thought that was new tech. lol

I'm waiting on an affordable robotic welding unit, that is programmed to serve up a cold beer at the same time. Watching all that work could make a guy thirsty. Hopefully the Germans will be the first to market. Their precision engineering creates some great beers. 🤩

Hold my keyboard and watch this! 🙃

Spent yesterday relearning what was forgotten from last weeks practice. Then moved on to run horizontal beads on a vertical plate. End of the last session decided it was time to initial the mess I'd created. 🤣

Will make a good exterior door stop. 😉

Hold my keyboard and watch this! 🙃

Amazon Prime day, has the fit up table I've been looking to get for a smoking good price. Just ordered it! 🤩

I've been looking each day for a good deal on this table for the past week. Same table as the Harbor Freight Titanium, just different color handles on the clamps. Best price I missed out on was $170. So this deal at $136 makes me very happy.

Hold my keyboard and watch this! 🙃

Started on the first "real project" that needed welding. Have an older Big Tex utility trailer where the trailer lights are mounted off the bottom rail. License plate was so low it was almost dragging the ground. Moved the license plate to the tailgate (made by previous owner). This week I cut off the light brackets, and welded them about 2/3 the way up on the rear most rail. Puts them about the same height as a normal passenger car.

Thin gauge metal that I got to practice uphill welding on. Came out pretty okay. lol

First attempt getting the settings reasonable:

Second attempt on the other bracket a bit better:

Thankfully this isn't a high load/stress application. lol having a lot of fun melting metal. 😎 Just need to finish re-wiring the trailer, then it will be time to move on to the sidecar brake bracket assembly. That is going to be a lot of fun.

Hold my keyboard and watch this! 🙃

Posted by: @nedDave is a member here. Goes by the handle davefran. Dave helped me do the DeDome mod on both my R1150GSA rig and my R1200GSA rig.

On my R1150GSA rig everybody who drove it said it was brilliant. Unfortunately, I totaled that rig.

On my R1200GSA rig, I had the DMC steering mod, the DeDome telelever with a 5/8-inch mod, and then I also converted the front wheel from the stock 19-incher to a 17-incher from a R1200RT (about 1-1/2 inches shorter in overall diameter). The result, then, isn't a fair representation of what the DeDome mod will do by itself. My three mods together I find to be tremendous. Other guys who drive my rig find it to be too "twitchy." Except for one guy who I loaned it to for a week -- he said it was twitchy on Day One, on Day Two he said it was getting better, and by Day Three he loved it. So the twitchiness experienced by the brief test riders might just be a matter of getting used to it.

My prediction is that you'll be super happy with it. If the steering ends up feeling too light, go on a 3-day trip to retrain your brain! If still too light, try less air.

Sounds like a well-thought-out setup—amazing how much difference a few mods can make once you get used to the feel!

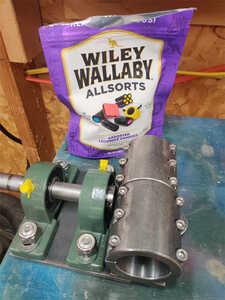

Started work on the sidecar brake project. Will be a lot of fun. Today's work was:

- Sizing the O.D. of the DOM tube to fit the I.D. of the pillow block bearings.

- Drilling the base plate to mount the pillow blocks.

- Test fitting the DOM tube into the bearings.

Don't have access to a lathe, so I used the drill press, and a couple of files. Only needed to reduce the O.D. about 0.004" so that went pretty quick.

In the category of "operant conditioning/positive reinforcement" training, we have a new bag of training treats. 🤩 Three quality exercises complete = three treats.

Can't wait for tomorrow's session. ![]()

Hold my keyboard and watch this! 🙃

Enjoying the use of the new fit-up table. Noticed Harbor Freight is having a parking lot sale this coming weekend, and has the same table (Their Titanium brand) on sale for $150. That sales starts today for Harbor Freight "Inside Track Club" members.

Meantime, between rounds of fetch, obedience training and... Squirrel!!!!! I've been "fitting up" the pieces to create the sidecar brake lever assembly. Had more fun with the new welding gear. What a fun way to start the week. 😎 The practice weld "coupons" make a great platform to keep excess heat off the thin metal top of the table. Should help stave off warping the top when welding thick plates with longer beads.

Next step is to remove the powdercoat on the section of sidecar frame tubing where this will clamp to. Need to get the exact sizing (I think it is 45mm) to properly size the I.D. of the tube clamps, before welding them to the bracket. Ukranian steel tubing, and U.S. sourced clamps aren't quite compatible. lol

Hold my keyboard and watch this! 🙃

Mating European tube to American clamp.

This clamp is designed for high strength use on tube chassis. As such the I.D. is pretty exacting at 1.750". I like these clamps for their strength, and "weldability". On the other side, the frame tube of the old Dnepr isn't so precise. Not quite round, not quite the same thickness along its length, etc.. So I took the clamp to an old school machine shop to have it bored.

Once it is back, I can trim the bottom bracket to the correct length and weld it to the clamp. Here is the concept. Overkill, but so is the whole rig, so it kind of fits the theme.

As I'm walking into the machine shop office I see a very old piece of paper with "Help Wanted" taped to the door. First question from the owner of the shop is "When do you need it?" My response, "when you can get to it." We then spent about 5 minutes lamenting the lack of people willing to work in the skilled services industries. Duly satisfied that I understood his plight, he gave me a grin and said "I'll work it in for you."

Spent the ride home thinking about offering my services part time to help out. Man, the smell of cutting oil and melted metal is seductive! If Channel could bottle that, I'd marry the first lady who wore it. Came to my senses after getting back to rural cattle country smells. But still, it is alluring. Many fond memories of my old garage smelling like that.

Hold my keyboard and watch this! 🙃

Aromatherapy is a powerful drug ![]()

Two Million Mile Rider

Exploring the World in Comfort

As we sail into the sunset of retirement I marvel a little at the reality of do or die.

We are made to wear out and not rust out.

Corrosion is a sneaky thing.

A lack of movement allows it to grow un checked or noticed.

Keeping busy allows us to at least monitor the rattles and squeaks.

The variety of what to do is unending it seems.

Some of us you can guess what country they are in by the day of the week.

Or was that the day by the country?

The bug or is it lack of other skills?

Keeps lots of us messing in workshops.

Or riding the things we mess with.

Within 200 metres I have both lawn bowls and ocean for fishing.

But nope I make noise dust and sparks.

I do think I should ride more.

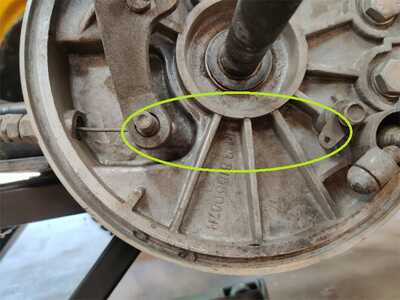

While the frame clamp is being machined, it seemed prudent to inspect the sidecar brake assembly, and clean/lubricate/adjust as needed. Glad I did. The lever return spring is missing. Found a few bits of it in various places. lol

So now I'm looking to see if there is a U.S. source for the oem spring. Searched Soviet Steeds forum without success. So I put a post up just in case someone knows. Mean time I'll come up with something to get it functional. Have a kit of assorted springs to choose from.

Green oval is where the missing spring should be.

Short of needing some cleaning, lubrication and adjustment the assembly and shoes are in great shape. 😎

Hold my keyboard and watch this! 🙃

Scott, if you don't find a suitable spring in your own parts collection, (which you probably will), contact Chuck @54vintage , as he may have THEE spring on hand.

The Ural cT chassis that is being used as the frame for my cargo sidecar rig, will NOT be using the drum brake, just the backing plate, so if that spring is the same one, he may have that available.

Chuck's email is: pica-pica1@hotmail.com

Two Million Mile Rider

Exploring the World in Comfort

- 29 Forums

- 11.9 K Topics

- 93.6 K Posts

- 2 Online

- 5,630 Members