The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

Trying to get a rig in and out of a CONEX

Gentle riders,

I have a quandary regarding getting my rig in and out of my storage container (aka: CONEX). I have a 2005 GL1800 ABS Honda Goldwing with a DMC Liberator 2-person sidecar. When I tried to put my rig into the CONEX I used three aluminum six-foot ramps – two stacked on top of each other (under the motorcycle component) and a single one under the sidecar. I failed to use the enclosed tie-down straps and the bike shot one ramp backwards and its weight bent the other. The bike was high centered and I had several friends lift the rig into the CONEX. Now I looking for an alternative to using those ramps.

I have been researching building a ramp system out of two sheets of 4’x8’x ¾” plywood and using the remaining aluminum ramps to reinforce it. The CONEX has a ramp useable area of 85” (7.09’) across its doorway and is 10” off the ground. The rig has a wheel base of 69” (5.75’) with a total width of 82” (6.83’).

I am no engineer and not exactly sure if I am approaching the ramp solution correctly. Has anyone contemplated such a build and what did you determine – build or not? I also have looked for a commercially available metal ramp solution but all I have located are too narrow (including those for ATV / UTV machines). Has anyone approached such a problem with eye towards a commercial aspect?

I am open to any and all ideas regarding my CONEX ramp dilemma.

Hi Steve and welcome aboard

just a questions first

How high is your container off the ground, this will effect the answer to your question more. one thing I found when I was using light weight alum. ramps going onto a normal flat bed trailer was using something in the middle of the ramps like a jack stand was critical to prevent them from bending. securing them is the first thing ALWAYS!!!! if you were to go the industrial direction I would look at alum. car ramps. the ramps with my car hauler are alum and handle the rig perfectly and don't even try to give.

@aceinsav, his Conex is 10" off the ground, so I am hoping that Steve Glass was meaning...that the floor inside the Conex is 10" higher than the ground surface, ergo, he has a drop of 10" from the Conex floor to the ground.

I agree with the suggestion by Ace....use CAR ramps, vs motorcycle ramps. They are wider to accommodate the car tire width, and are built to handle the weight of a car, rather than a solo motorcycle.

In lieu of buying car ramps, which actually can be found at most auto parts stores, and even the heavy duty plastic ones can handle the weight of a car, or...motorcycle sidecar rig, what I was thinking is to get two....2" by 10"....by 10' long boards, or even 12' long if you can find them. Use these 2 x 10 boards to serve as your ramps. What I would do is, drill a 1/2" diameter hole at the end of each board, so that both boards have a 1/2" hole almost at the end...both ends....and also drill a 1/2" hole into the floor of the Conex box, just inside the door opening, so that when each of these 10' or 12' long boards are placed where they need to be in alignment with your wheel TRACK...not wheelbase...but wheel TRACK...then you drop a 1/2" bolt into the hole of the board, and that same bolt goes into the hole you drilled into the floor of the Conex box.

Do that for both boards, have a long bolt that drops into the hole of each board, and slides into the holes you drilled into the floor of the Conex box, so that keeps each board from sliding out, or flying out, when you are removing the sidecar rig from the Conex box, or putting it back into the Conex box.

AND....for that hole you drilled into the other end of each board, get a long spike that you can push down through each hole, and push into the ground, to secure that end of each board from moving around on you, as you move the sidecar rig up or down those wooden ramps.

Paint the tops of each wooden ramp with DECK paint, that has the sand in it, for traction when going up or down the ramp.

For added security, I would add a 2 x 4 to the underside of each wooden ramp, in the very center of each ramp, but lengthwise, so it acts as a girder, a backbone, to the underside of each wooden ramp. And, in my world, I would install that 2 x 4 converse to the wooden ramp, so that the 2" section of the 2 x 4 is touching the 2 x 10 wooden ramp, then screw 4" deck screws down from the top, through the wooden ramp, and into the 2 x 4, because installing the 2 x 4 conversely to the 2 x 10 would give it more rigidity.

All In costs for doing this job...less than $ 66...and 66 cents

Oh, and BTW, Steve Glass, I was deeply offended when you addressed us as....Gentle riders ![]()

Two Million Mile Rider

Exploring the World in Comfort

I, too, Steve have had a challenge getting my rig onto a trailer, not unlike the issue you are experiencing. The ramps I had used were rated at 750 each and the Royal Star rig could be dragged up by a winch at the end of the trailer. It worked for a while but the rig eventually collapsed the steel ramp, necessitating an emergency welding reinforcement just before the 2024 Rally in Iuka, MS.

Since then we have sold the Royal Star rig and acquired a Goldwing 1800 rig that would NEVER be able to use any portable ramp.

I agree with Miles' suggestion above about wood ramps, though I would possibly offer a slight modification. Use 10" 2x10s stacked and screwed together in the shape of a ramp and cut a bevel onto the leading edge of each stacked segment. I built such a thing for my VW to get it off the ground for oil changes and it worked a trick. Since this isn't meant to be a traveling device, making the base segment 6ft long and shortening by a foot until you get to your 10" rise would be fairly effective and pretty simple. Using a chunk of rebar to anchor it to the ground if it's meant to be a "permanent" installation.

Illegitemi non carborundum est!

Good looking rig! (based on your avatar picture). 😎

Hold my keyboard and watch this! 🙃

Posted by: @scott-hGood looking rig! (based on your avatar picture). 😎

Oh, Great Scot, how can you say that ? There is not a hint of YELLOW anywhere on his Blue rig.

![]()

Two Million Mile Rider

Exploring the World in Comfort

Posted by: @miles-laduePosted by: @scott-hGood looking rig! (based on your avatar picture). 😎

Oh, Great Scot, how can you say that ? There is not a hint of YELLOW anywhere on his Blue rig.

The amber turn signal lens???

![]()

Hold my keyboard and watch this! 🙃

I agree with FM that a 6' or 8' ramp is too short. You have the high centering problem and of course the steepness.

Stacking two 2x10's to give you the stiffness you need is OK, but DANG! those be heavy ramps! FM's suggestion of using a 2x4 for the stiffener might be enough. Another option would be 1/8" alu U-Channel which is pretty stiff.

Us fureigners need pictures.

Conex?

On another thread they had something called wet snow???

Maybe I could take a picture of my trailer ramp.

Actually I put one up on my thread.

It weighs 50kg made of steel and pine.

1.5m long with the trailer being 450mm high

Handles a 750 kg vintage car just fine.

Driven or winched.

Probably cope with a leadwing also.

Of course it's on a fixed hinge.

But if you can decipher Miles's input it all good.

Posted by: @s_glass@miles-ladue Oops -- wrong picture...here's one with a little yellow for contrast!

-- attachment is not available --

Steve, thanks for the larger picture, and despite your earlier claim to not be an engineer, I must say that when you combine ALL the pictures of ALL the sidecarsists on these forums that are actual engineers, the result of that mashing up of all those pictures is that it comes out to look like YOU...ergo you are an Engineer Emeritus.

BUT...we need a more recent picture, to see how you have aged, as that picture is now more than 3 years olde.

In the newer picture, "I" need to see that you have installed a Bridgestone BT-46 tire on the front wheel of your '05 Wing, and...that you have a nice YELLOW lens film over the lower front driving lights, to protect those lower lights, and to have car drivers SEE yu, in a sea of white lights.

Question: What YEAR was that DMC Liberator sidecar made ? I remember those at DMC, in their original Enumclaw, WA location, as they were only 60 miles from me. How many years has that DMC Liberator sidecar been attached to your '05 Wing ?

Are you running a Car Tire on the rear wheel of the bike ?

And lastly (for the moment), how many MILES are currently on your '05 Wing ?

Oh, and Steve, whilst I have your brief attention, think about having a local shop in your area printing out a piece of WRAP material, that mirrors the image of the light assembly on the right front of your sidecar...then have them install that mirrored image onto the left front of your sidecar, so that it "appears" that you have a SET of headlights on the very front of your sidecar. AND....get a OEM...Honda "car" H, the silver metal looking H, and stick that in the very center of your sidecar front grill area, so it adds to the Honda sideCAR impression.

Two Million Mile Rider

Exploring the World in Comfort

Sweet! 🤩

What a good looking rig. I bet it drives beautifully. 😎

I'll second what Miles is saying on the yellow film for the fog/driving lights. We are programmed to see white lights, and so they become ignored. Yellow is rare, and makes the vehicle stand out. 👍

Hold my keyboard and watch this! 🙃

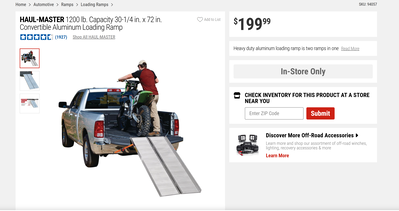

If you picked up two sets of these folding ramps, you would probably be fine...

I bought one set for use as a wheel chair ramp for a friend to be able to drive a relatively heavy electric chair up a few step front porch into my not ADA friendly CT house, a long time ago.

I have found them to be quite strong, but easy to fold up and store. Rated for 1,200 lbs per set, so you would be ok, even with some derating. Catch them on sale or w coupons though. I think I paid something like $79 for them 10 years ago.

I would probably not do plywood. Not much strength for side deflection.

- 29 Forums

- 11.9 K Topics

- 93.6 K Posts

- 8 Online

- 5,629 Members