The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

Spacers or bearings

Folks -

Look for additional thoughts on this.

My 2011 R1200GSA came with a spare front wheel which I would like to use as a sidecar wheel instead of the Ural drum brake wheel that is on it currently.

The R1200GSA came with a 25mm front axle. The Ural tub has a 20mm axle and I need to decide which is the best way to pair them.

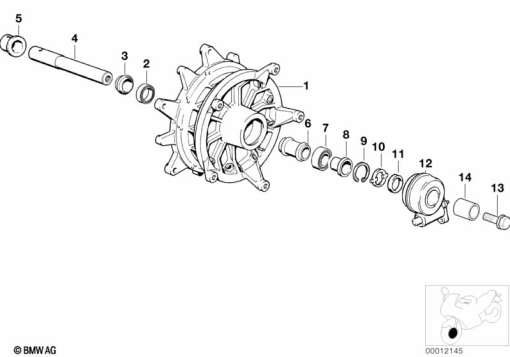

Option A. Use spacers. BMW makes a spacer for the R1150GS/A which has a 20mm ID and a 25mm outer diameter.

Pros:

a. I have two of them but would have to get them turned down because they are only 20mm at the chamfered edge (see pic).

b. The inner spacer tube which runs through the hub from bearing to bearing is also 25mm. Using the spacers would support it a bit, keeping it from moving or flopping around.

c. Others have used spacers so they could swap different wheels on a GS (ie. street, offroad)

Option B. Replace the bearings with ones the same width and depth but with a 20mm ID.

Pro:

a. The axle would rest right on the bearing instead of having a spacer between the axle and the bearing inner race.

b. Wouldn't have to take the spacers to a machine shop.

Looking for factors I might not have thought of.

Thanks,

Drew

Replacing the bearings on a R1200GSA wheel is not too tough. I've done it with a buddy. New bearings don't cost much and go in OK if you take them directly out of the freezer.

Kirk's done a good (and funny around minute 13) DIY video --->

But if you use the sleeves, then your front wheel and sidecar wheel would be swappable, even by the side of the road or in a motel parking lot. Thinking about that for when you're on a long trip.

Good point about being able to swap them.

What would be involved in swapping to a 25mm axle? Mark me down as another who likes the "hot swappable" wheel idea. 🙂

If I were running spacers between the axle and the bearing, I'd want the spacers to be somewhat fixed so they can't rotate. I've had great luck with loctite 638 for situations like that.

Hold my keyboard and watch this! 🙃

Quote from sheath on November 27, 2023, 8:48 amWhat would be involved in swapping to a 25mm axle? Mark me down as another who likes the "hot swappable" wheel idea. 🙂

Cutting, welding, and worrying. Not a project for right now.

However, it's a good thought for later - which makes me lean more towards the spacers as a temporary solution until I would do an axle swap.

I can't see a way to fix the spacers. They are under the seal.

Quote from sheath on November 27, 2023, 8:48 amIf I were running spacers between the axle and the bearing, I'd want the spacers to be somewhat fixed so they can't rotate. I've had great luck with loctite 638 for situations like that.

Quote from Drew on November 27, 2023, 10:52 am

I can't see a way to fix the spacers. They are under the seal.

I have to politely disagree with Scott @sheath on this, and inform Drew @Drew that in my world, I would NOT loctite the spacer into a fixed position.

I generally PACK the inside of the wheel hub with a lot of Timken RED waterproof bearing grease, THEN squish the spacer into the wheel hub, so that there is a lot of the grease on both the outside of the spacer/...between the spacer and the hub, and on the inside of the spacer. Then I install the wheel bearings on both sides of the wheel hub, then install both wheel seals on both sides of the wheel hub, install the wheel/tire into position to be mounted on the front forks, then slide the axle in and through, squishing out Timken RED waterproof bearing grease as I slide the axle through, collect all that excess bearing grease, send it in an envelope to New @DRONE, as he collects slightly used bearing grease (that is a joke, do NOT send Ned all your slightly used bearing grease), then secure the axle in place.

If you secure the spacer into a fixed position inside the wheel hub, this CAN allow the rotating wheel, with fixed position axle spacer, to chafe against the fixed axle that is not rotating, causing friction, which results in wear.

Two Million Mile Rider

Exploring the World in Comfort

Quote from FlyingMonkeys on November 27, 2023, 11:35 amQuote from sheath on November 27, 2023, 8:48 amIf I were running spacers between the axle and the bearing, I'd want the spacers to be somewhat fixed so they can't rotate. I've had great luck with loctite 638 for situations like that.

Quote from Drew on November 27, 2023, 10:52 am

I can't see a way to fix the spacers. They are under the seal.

I have to politely disagree with Scott @sheath on this, and inform Drew @Drew that in my world, I would NOT loctite the spacer into a fixed position.

I generally PACK the inside of the wheel hub with a lot of Timken RED waterproof bearing grease, THEN squish the spacer into the wheel hub, so that there is a lot of the grease on both the outside of the spacer/...between the spacer and the hub, and on the inside of the spacer. Then I install the wheel bearings on both sides of the wheel hub, then install both wheel seals on both sides of the wheel hub, install the wheel/tire into position to be mounted on the front forks, then slide the axle in and through, squishing out Timken RED waterproof bearing grease as I slide the axle through, collect all that excess bearing grease, send it in an envelope to New @DRONE, as he collects slightly used bearing grease (that is a joke, do NOT send Ned all your slightly used bearing grease), then secure the axle in place.

If you secure the spacer into a fixed position inside the wheel hub, this CAN allow the rotating wheel, with fixed position axle spacer, to chafe against the fixed axle that is not rotating, causing friction, which results in wear.

Since FM has over 2 million miles versus my less than 2 thousand, I'd definitely follow his advice over mine. 🙂

My thought was to adhere the spacers to the axle, not the bearings though. Similar to sleeving the axle to 25mm. Otherwise he wouldn't be able to do a "hot swap" between the steer wheel and sidecar.

Hold my keyboard and watch this! 🙃

Quote from Drew on November 27, 2023, 2:16 pmQuote from FlyingMonkeys>> squishing out Timken RED waterproof bearing grease as I slide the axle through <<That's been my usual method. Never can have enough lube.I can't affix the spacers to the axle. The spacers have lips that are larger than the wheel bearings. Loctite wouldn't hold and anything permanent would prevent me taking off the wheel.Besides I agree with FM that letting the spacers spin would prevent them from wearing into weird shapes.

Got it! I thought you were machining the shoulders (lips) down.

On my 1100 the wheel bearings and the spacer are pressed into the hub. So no chance the spacer touches the axle or the same thing that Miles wrote about would happen to the stock axle on the bike. Didn't realize that was different on the newer GS bikes.

Hold my keyboard and watch this! 🙃

Sheath -

You actually have the same spacer (part #8) on the left side of your front wheel as the ones I bought to do this conversion because your axle is 20mm.

Yours has a lock ring after it (#9), then a driving dog, and the speedo. (See pic)

Since I will be running a 25mm outer diameter spacer on each side of the wheel to center it on the Ural axle I won't need the lock ring to keep the inner spacer from moving outward and the lip on it will keep it from moving inward.

The machine shop had another take all together. They said there wasn't enough of a lip to grab the spacer so they would have to put it deeper into the chuck or the wouldn't be able to turn it evenly and I'd end up with an oblong shaped spacer. Putting it deeper into the chuck would mean they couldn't turn it all the way down to the lip.

The result would be a spacer that went part way in then had a gap before the lip.

They could make me spacers but the cost of the materials alone (stainless) would be more than the cost of buying the bearings and going that route.

And that's before their labor costs.

I'm going to go with bearings for now. If I decided I want the ability to swap the front wheel for the sidecar wheel, I can get spacers and bearings to match.

- 29 Forums

- 11.9 K Topics

- 93.5 K Posts

- 5 Online

- 5,615 Members