The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

I'm getting pretty excited. A Buddie of mine is going to bend some of the pieces I need for my subframe after work tomorrow:o) I am going to try and get it tacked together this weekend.

I cleaned out the bay in my garage. I have just enough room to build the frame and attach it to my tug. I can't wait. Tomorrow, I'll probably move the body over next to the bike to "test fit" it:o) I want to see if I'm going to have any issues. This way I can see how high it needs to be and how close to the bike I'm going to want it. I'll be sure to get some pictures.

Initially to align everything I'm going to lay out some lines on the floor so I have a place to measure from. This will aid in lining up the subframe. What would be a good distance for the width from center of bike tire to center of side car tire? I'm planing on about 10" of lead. Does this sound good?

The frame will be mainly 1 1/4" DOM tubing with a .120" wall thickness. Should this be fine? Or should I try something different?

Thanks for any input, WesP

The 10" wheel lead sounds OK.

I usually set up around 12" frame to frame. That leaves plenty of space for the pilot and saddlebags if used. It also leaves a bit of working space for some maintenance issues.

The wider the track the harder the steering but more stability.

It's a tradeoff.

Lonnie

Northwest Sidecars

I was planing on about 10" to 12". Between the tug and the car. I still want use of the highway pegs. That is why I'd like to have the car next to the bike for a "test fit". There should be plenty of room because the front of the car narrows up pretty nice. I'll just have to see:o)It's still going to be fairly wide. It's looking bigger than I expected, for some reason.

Thanks, WesP

We usually go with a minimum of 48" track width.

1 1/4" x .120 DOM may be okay but I would probably go with 1 1/2" or 1 3/4". We use 1 3/4" most of the time. On advantage to the larger tubing is it gives more surface area if you are running a tube inside a tube for a pinch block deal for the lower mounts. It also gives more welded area where the connections are, especially swingarm attachment points, shock mount areas and such.

Can't wait to se more pics 🙂

Well I have the body next to the tug:o) I think it will be great with 12" of clearance. I'll plan on that. I have the garage floor marked. I think that was a good Idea. I am going to make a couple changes to the frame. The back will taper in a bit, maybe. I already have the 1 1/4 tubing. I'll add a couple of extra gussets and a cross tube where the axle will hook on. Thanks alot for the help.

Wes

Looks great. Like the rack on the back of the bike too !

Wes,

I really admire your woodwork, following your progress has been fun. I wish there were more posts like yours.

Are you talking about 12" clear of the rear case? That's mega-wide. Remember that you will be dealing with inertia on every start and stop. When you start out the inertia of the sidecar will make the rig pull to the right. On stopping, the sidecar will try to pass the bike and push to the left. You can deal with all this with muscle. Generally a wider rig [up to a point] is more stable but if they get too wide, they are a handful to drive.

I'd suggest that you set up the bike so that the track width will be adjustable. That way you can start wider than you think you'll need and narrow things up until you find your "sweet spot". Keep up the good posts!

Thanks Claude. I'm pretty excited. As soon as I get the floor cleaned, I'll get the body back into the other shop and I'll start on the subframe.

The luggage rack is something I'm messing with to tie the sidecar and the bike together. It will be Oak when done.

The 12" is from the frame near the footpegs. There will be around 5" by the saddlebags.

Wes

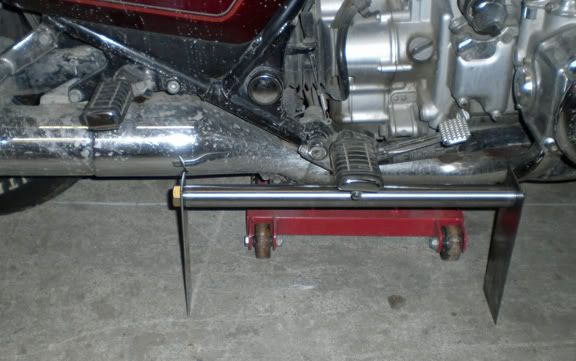

I made a quick stand for the bottom mount bar out of some scrap metal. This will let me keep the bar parallel with the ground and the bike and be hands free. I drilled and tapped the bar this morning. After placing it next to the bike, I think I can go with a longer bar. I think that would be better?

There are two bolts behind the rear foot peg. I am planing on making a bracket that mounts here and will have a tube coming down to the bottom bar. This will give three places that th bottom bar will be mounted to. It will probably have to be bolted on. Any input is very welcome.

Thanks, Wes

Many riggers will make a subframe that uses the mounting points for the centerstand [since you won't need it anymore]. It's probably the strongest mount point on most bikes. Looking good, keep the posts coming.

There will be 3 mounting points for the bottom bar. In the front, I will use the bottom engine mount bolt. I will probably replace this with a grade 8 bolt. In the back, I am using the center stand mount (already removed the stand) and there will be a bracket bolted to those two bolts that I pointed out behind the rear foot peg.

Originally written by Wngnut on 3/8/2009 6:15 PM

I made a quick stand for the bottom mount bar out of some scrap metal. This will let me keep the bar parallel with the ground and the bike and be hands free. I drilled and tapped the bar this morning. After placing it next to the bike, I think I can go with a longer bar. I think that would be better?

There are two bolts behind the rear foot peg. I am planing on making a bracket that mounts here and will have a tube coming down to the bottom bar. This will give three places that th bottom bar will be mounted to. It will probably have to be bolted on. Any input is very welcome.

Thanks, Wes

Getting the lower mounts spread out more won't hurt. You can run the subframe back farther if you want and still get good support by triangulating up to the centerstand mounting area.

Not being critcal Wes. Looks like you have thought out things well.

Keeping the lower mounts in line and level is a good move!

- 29 Forums

- 11.9 K Topics

- 93.5 K Posts

- 3 Online

- 5,624 Members