Is it possible to build a detachable sidecar for this motorcylce?

Hello everyone!

I am wondering whether it is possible to build a detachable sidecar for motorcycles like these:

It is a 70cc Honda bike (Honda CD70) that weights around 175 pounds. I am basically interested in making one that can be used as both a sidecar for a passenger and for transporting small goods. High speeds are not a concern, since these bikes top off at around 50 mph, even without a sidecar. With the sidecar, its good as long as it can hit at-least 35 mph.

Regardless of whether it is possible or not, I would greatly appreciate some feedback! Waiting for your replies!

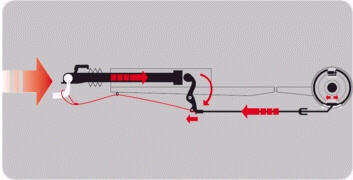

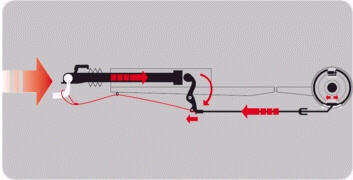

Possible? Sure. BUT... detachable is a funny word. It's a matter of just how much trouble is involved in attaching a removing the hack and a great deal of that depends on how much mounting hardware you are willing to leave on the bike when the side car is not attached. Also, that 35 mph thing might be an issue. The is a picture below of my wife's C70 rig. On any given day 35 mph may or may not be attainable. On good days 35 is "all in" for the tiny bike. Some improvement might be had by switching the sprocket but that would take some experimentation. First thought would be to lower the ratio to get more low end to pull the hack but that will potentially kill your top end. Like I said, maybe with some experimentation.

The mount on her C70 was custom built, there's a fixed large diameter tube that goes from the diagonal down tube to the sidecar frame. That is fixed to the down tube by a made to fit collar that goes around the tube. The second brace goes from the rear top shock mount to the sidecar frame and it is adjustable. That's it, just two mounting points and it IS NOT a quick disconnect situation. A different design might permit quick disconnect but remember that you want to maintain alignment when to remove and replace the hack.

Is there any sort of frame tube under that tank?

Nice Supercup (copied partially from NSU Quikly)

If I remember right the one I rented in 1988, the frame are 2 pressed sheet metal halfs welded together just like the NSU Quikly/Fox/Max.

The wall must be pretty thick. (NSU Max had about 4mm)

The tank is under the seat part of the frame.

I am sure the kids and dogs love this supermarket basket.

Muy guess is that due to low speed and small front area that as rig this bike will not loose as much top speed as you loose on a normal rig.

Enjoy.

Sven

@Al Olme @Peter Pan

Thank you both for your valuable input :))

I actually want to make a prototype, because I was wondering if I could introduce sidecars to Pakistan. They would be mainly targeting the lower middle class who can afford such 70cc bikes, but not small cars. In essence they would get a small car for a fraction of the cost (Thinking of retailing the sidecar for $100-150 - not sure if possible). I guess even 30 mph is fine for the 70cc.

The main reason I want it detachable is that most of the lower middle class only owns one bike, and here in traffic they weave in and out constantly to get everywhere fast. With a sidecar they wont be able to do that. So if its permanent, many would shy away from it. However if it is detachable (ideally taking less than 10 minutes), they can use it when transporting their families/ groceries etc, and take if off when riding solo.

I am attaching a few pictures of other 70, 125 and 150 cc bikes common here.

Once again thanks for the input!

The frame on this small Honda is very strong. They were designed after someone looked at the bone from a t bone steak. We broke almost every other part of these bikes but never bent a frame.

mrmustash

Sorry Dan,

I looked at Al's foto, not at the one you provided.

It would be good if you provide some information about your local situation and the plans that you have.

A personal once in a lifetime project is one thing, an industrial project is a total other pair of shoes.

Have a close look at the projects our Polish friend Igor has done. He is a real hands on inventor / "maker".

His user name is "c64club".

I live in a once upon the time 3rd world country myself and spent the last 27 years helping in development...you get pretty fast disappointed when you see how a country with once "social conscience" turns into "total egoism" when the people start to earn some money. And suddenly the Chineese motorcycle garbage and huge 4*4 luxury cars overflow the few roads. (in 30 years vehicle population multiplied by 9 on the same amount of roads- now not even on solo motorcycle you are able to move at a reasonable pace) So if you like we can talk over the phone for to get some more input faster and later see how to help you in your projects.

My international telephone number is (++506)-22688785 or celular ++506-88329087. or post your number and I will call you through. In 10 minutes talk often you resolve more questions then in hours writing. If I am right our Centralamerican time is Greenwich minus 6hours while Pakistan should be plus 5 hours. = 11 hours difference.

So when I enter office before dawn at 5am you should be still in office at 16:00 = 4PM of the same day.

Best regards.

Sven

Given the small size of the bike, I don't think the stresses on a sidecar frame would be huge. However, also having spent a good chunk of my career working all over the world, I can envision somebody buying one of your sidecar rigs and going into the moving or hauling business.

But, if intended for passengers or light loads, yet, I could see a quick disconnect that uses hardened pins or miniature version of trailer hitch connections. If you make all 4 mounting points ball type mounts on the bike, then you could have collet type mating connections that could be taken on and off without disturbing the alignment. You would have to put some thought into how you would design the collets. Last thing you want is for one to come loose while the vehicle is in motion. Perhaps a spring loaded coupler that has a safety pin behind the collar. Think of an air hose coupling. Now replace the male piece with a ball mount. Modify the other female couping to match it. Pull back on the outer collar and it releases. So, with the collar in place, you have a hole drilled directly behind it that accepts a safety pin to keep the collar from moving backwards and releasing the ball. I can see less than 10 minutes to remove a lightweight sidecar. Of course, knowing the 3rd world, about a week after someone buys one of these, they will lose or discard the safety pins.

Another possibility for quick disconnect would be based on how you make your subframe. If you make it tubes that bolt to the bottom of the bike, you could make a tube in a tube design. A tube mounts to the bike and a second tube slides inside it and is held in place with a pin or two pins for safety. The sliding tube has the ball mount like a conventional bottom mount. After you get it adjusted, you pull the pin and the sliding tube comes out of the mounted tube. The top struts can just be held with hardened pins and hairpin clips. It's a light bike and sidecar so I think this would be fine. They haul huge trailers with the entire load on a 1/2" diameter pin.

Now, see that yellow sidecar in Al's photo. Make your car like that. Only offer two top halves. One like the one in the photo for a passenger and the other a big box with a hinged lid for carrying goods. A couple of screws is all you need to remove to change the top halves.

Your price goal is a tough one. But the labor rates over there are peanuts compared to here, so maybe possible. Since you are making these for one model of motorcycle, you probably could do without a lot of adjustability. I would think that Hondas are pretty uniform so your sidecars could be made to fit and be properly aligned with little to no adjustment. That would be a major cost savings.

Good luck,

Rob

@Peter Pan Thank you so much for the offer 🙂 I will definitely call you when soon, after I do some basic research. I'm sure you can give me more information in 5 minutes than I can get in multiple days myself.

@Snakeoil Haha yes people here are masters of improvisation, and use things for purposes different than the original intended ones. Your thoughts are very valuable and I will discuss them with someone who has a more mechanical background. I am not sure if I can get it done in that price, but I think it might be possible. You can find things real cheap here if you know how to look for them.

Btw we also have a dedicated transporter like this on the streets over here.

I believe that Snakeoil's ideas are innovative but maybe overly complex for the local tech. Simple clevis connectors would do the job for a small fraction of the price and much more simply. There are a few pictures of clevis connectors and pins attached. These are so simple that they could be locally made but I'll bet such connectors are in any country. I like the removeable pin with the snap on keeper. Too fancy for this application but a nice idea.

I was wondering when someone would mention the tuk-tuk type vehicle. With those existing, what is the need for a sidecar rig? Are they too expensive?

About the tubs themselves. The molded fiberglass tub on Maryann's rig is very small and again overly complex. For passenger seating look to the open seats used on the sidecar motocross and "adventure" type rigs. I've attached a picture below. It just a seat on the frame. This one is a little nicer and uses a sheet metal and tubing mud guard. As to the cargo box... well, "box" says it all. Actually a simple platform with some tie down points would be more more flexible.

It appears that the bare basics are what's needed here. Utility without fluff at the lowest possible cost.

one thing that is easily to obtain at low price or from scrap yards are car steering ball joints. My neighbour uses one for hook his trailer onto his 125ccm bike for several years now. The only difficult part was the conical hole for the receiver, that he made with a round file.

Though I am a friend of the toughHonda engine Dan proposes, but am afraid that the frame will not give him much choice to attach to. Soon there will come or began already a flood of cheap Chineese copies and crap in extremely diverse forms and shapes. A sidecar for different bikes will always involve lots of engineering and setup work for each model because of their unique geometry and stiffness needs.(ask our specialists here from what they got their grey hair) A simple trailer would be universal and much easier to adapt for any backyard welder and when you adapt a spring loaded trailer break then they would work even in steep terrain.

Living myself in a country with extremely steep mountains, which is not as hot as yours, I would always suggest 4 stroke engine with hopefully water cooling, or in case of air cooled engines, a forced fan cooling. In my Jawa I installed 2 strong computer fans that helped at least in downtown traffic. With any kind of extra load on a bike a fan will help to keep the engine living longer.

In my personal opinion the vast model and fabricator variety of nowerdays motorcycle market is in the end a robbery to the people. still 20 years ago with perhaps 6 main brands and perhaps 5 solid standard models each, that did not vary from year to year, most people were better off. I still consider my Honda XL200 and Vespa the most useful bikes I owned.

I would add this following famous farm moped to the list, never owned one myself but rented a more civilian version for a few weeks back in 1988 in Costa Rica. I'd buy one in an eyeblink. The semiautomatic gear box "¡with duplication!" was told to be eternal and out lasted more then one of his owners. Still 10 years ago I saw a modern version of it at the Honda agency.

Sven

What about a leaner?

Only two attachment points, and they go onto the strongest portion of the frame.

@Al Olme Thank you very much for that technical input. I myself am an engineer (Biomedical), but not a mechanical engineer so excuse my lack of knowledge :p

As for the rickshaws (tuk tuk), they are purpose built vehicles. They are more expensive, and a person who buys those is primarily going to be using it as a source of income (rickshaw/taxi driver). That drastically lowers the market for it. A detachable sidecar buyer can be anyone who owns a motorcycle - from an office worker to a delivery boy to an old man looking for cheap family transport.

And yes you are totally right about the no fluff only utility part, since the target market will be people on a very tight budget.

@Peterpan Our market is already flooded with chinese bikes, but they look very similar to the Honda, Suzuki, and Yahama 70 cc bikes here. Do you think they would require separate designs? I was assuming there would be a one design fits all type of sidecar for such bikes.

@michaelh Could you please elaborate on what a leaner is? Excuse my ignorance.

Hello Dan Johnman,

my personal experience tells me that any rig with less then 400ccm is bound to suffer "A LOT".

These mopeds are all identical on the photo...Possibly even the Honda is built in China. After having looked closser into a Korean 125ccm that had the engine mounts made out of just 2mm stamped soft steel (boiler plate)and having seen a "Quinko?" chineese 150ccm broken into half due to a very small sideward hit from a swaying car I am very suspicious about all these new "flood" bikes.

Here in our country the "flood bikes" are MUCH more diverse in styles and designs. therefore I was warning about the different design needs.

A small trick of an old collegue you might apply. He owns a farm way up on a very steep vulcano and owns a 175ccm Enduro bike with a trailer. He mounted a set of triple "Sandwich sprockets" and a spring loaded (double action?) chain tensioner for final drive plus a big fan. I haven't met him after his remodelation any more, but think that something like that could help you too.

The shown bike will definitively need a subframe as there is nothing to attach to.

Sven.

johnman - 12/7/2015 7:42 PM

@michaelh Could you please elaborate on what a leaner is? Excuse my ignorance.

Please understand I'm not expert on anything, but just throwing out a thought. A leaner sidecar attaches at two points to the tug, and is intentionally not rigid. It is alleged that it operates much closer to a m/c than a rig because the tug can lean, and with only two connection points, very easy to disconnect.

Here's a thread http://advrider.com/index.php?threads/leaner-questions.962947/, with some good illustrations of the type of sub-frame needed (as well as a couple of pretty hot chicks near the end of the thread! 🙂 ).

I would think that with the lighter weight frames of the bikes you're talking about, the leaner concept would stress the frame the least because it doesn't need upper attachment points.

johnman,

The issue regarding mounting is that in order to be rigid there must be either a large rigid custom made member or a set of at least three triangulating members. When making a "universal" mount, these triangulating members are attached to strong points on the frame. The problem is that the clamps used to make the attachments almost always slip. That puts the sidecar out of alignment at the least and in a dangerous failure mode at worst. Dedicated mounts for specific bike models can avoid this issue. NB- welding to the frame or drilling through the frame is not safe, especially so on small bikes with very light frames.

You could pick one [or more than one if the frames were identical, not uncommon on mass market bikes] and build a dedicated frame for that bike that would be safe. I'm not familiar with the litigation climate in other parts of the world but producing a rig that is known to have potential failure points is sure to get you sued. That said, it is done here in the US.

Some high line sidecar manufacturers in Europe have made bike specific mounts that join to a common sidecar frame that they use on all bikes. That might be an alternative for you. Make a standard sidecar frame with connector plates that are X cm apart and Y cm above the ground. Then make the bike side parts come out to those points. You might get your quick disconnect feature by that device and removal and reinstallation would maintain alignment.

Good luck.

- 29 Forums

- 11.3 K Topics

- 85.4 K Posts

- 3 Online

- 5,231 Members