The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

The mods are done

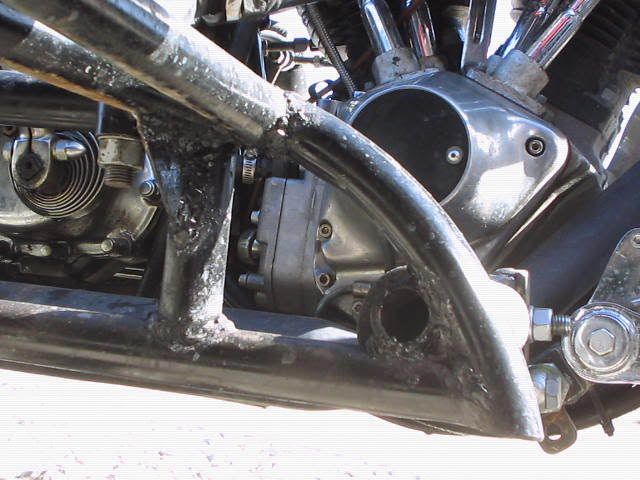

OK, does this look any safer than the 'test' mounts? We added a lower frame rail and moved the mount points down and foward. Now the s/c wheel lead is about 10.5" and the center to center wheel width is 52".

Looks like it will work.

I would have inserted a threaded shaft into the rear mount tube and gone straight into the sidecar frame eliminating the pad eye and the shear forces on the attachment bolts shown in pic 001.

Lonnie

Northwest Sidecars

Thank you, I am never done and any suggestions are always appreciated. Everything in my life is a 'work in progress'.

I agree with Lonnie as long the stud is a good quality steel bolt, no threaded rod from the next hardware store!

On top I'd reenforce the corners. You put a lot of force on welded tube pointing into one spot, that nearly alway will crack.

Old design principles:

Several weldings coming together in one point will crack, keep a small gap at the end clean.

Square frames twist, triangles are rigid because they have no change to go away.

Avoid long free hanging levers or to attach close to the pivot point.

You are right this whole life is a design project of continuous improvement, or as My Granny used to say: "You get as old as a cow and you still continue learning each day something new."

Good luck

Sven

Gusset and placement is fine.

The welding itself..........................

I would suggest a welding class or a lot more practice.

Sorry, You asked,

Lonnie

I did not do the welding, a man that fabricates for a living did that. The frame was even off the m/c with no body and no fender. It is not as bad as that first picture looks. He did some of the work while I was not there! I was not as happy as I should have been been. It gets better every day. Here is the rear, I flipped the lower strut and am thinking about changing the end by the s/c. He bent it, to straighten it out, when I asked to have it cut out and a new end welded in. All in all it is a lot better than what I had.

It can be true that a bad looking weld is okay as well as a good looking weld being bad. Hope yours are okay.

I would have added more support via a gusset to the end of that tube. Right now even with gobs of weld on it you are relying on th ewall thickness of the tube to take all loads. Even plugging the end of the tube woudl help some. See attached picture.

The welding in the picture may not look very pretty, but it looks a whole lot better than the welding on my Dneper.

I'd be scared.

- 29 Forums

- 11.9 K Topics

- 93.5 K Posts

- 8 Online

- 5,619 Members