The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

Thanks for the tip on the LED's :o)

I'm starting to get pretty excited. My list of "things to do" is getting shorter and shorter. My pile of finished parts is pretty big. I have finishing touches to do on quite a few things, but, I'm going to focus on getting it road worthy. Last weekend I finished the axle. I put a valve stem on the wheel and mounted my new tire. A couple more things to powder coat and I'll be able to assemble the frame. I have the body nearly ready to glass the outside. Just a very small amount of things to do on the inside.

Won't be long now, Wes

I made a table so I could manage the fiberglass cloth more better. The pieces will be big and I need somewhere where I can work on the cloth and not get it dirty.

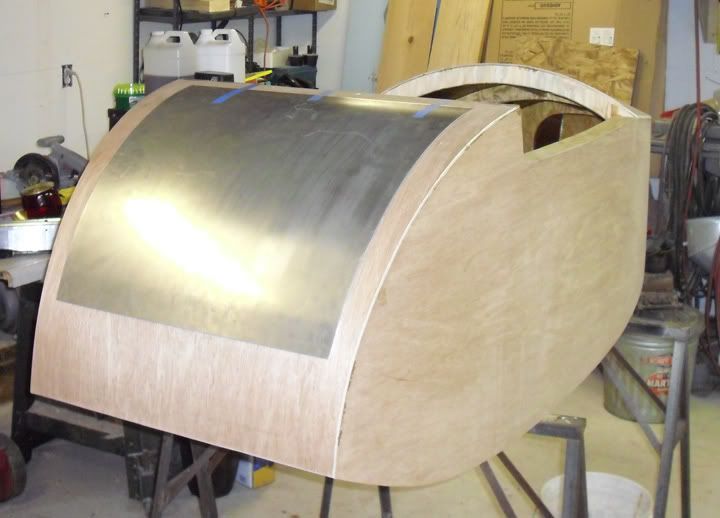

I went to a friends shop. He does a bunch of sheet metal and has a nice roll. We used it to make the trunk lid. You can see the gauge that I made to take with me.

Also started on a fender.

My help bailed on me, So I spent the day in my machine shop instead of fiberglassing.

I decided to work on the hub for my spinner. I did the first side earlier. I chucked the piece of scrap up in my lathe and indicated it in.

Here is an action shot.

After all the metal that wasn't a hub was machined and filed away. This is what I ended up with.

It looks pretty good on the wheel!!! I still have to drill the mounting holes and make a cap for it.

Now off to my Steampunk turn signal. That brass globe was going to be a reflector for mt light. I marked a 6" circle and notched it out with my bandsaw. It wasn't pretty but it worked:o)

I rummaged through my scraps. Here is what i found. A piece of brass plate and a short piece of shaft.

The shaft ended up being a different grade of brass. I decided to cut both circles out of the plate. There was JUST enough.

I started on the top piece. I chucked it up in my lathe and indicated it in. I bored out the bottom to fit the glass globe. I then turned it around and machined a shallow bevel on it and rounded all the corners with a file.

Here is what I ended up with.

It will look great polished up!!!

Later, Wes

The brass I worked with in the past often corroded and lost its shinyness.

So sometimes after polishing I cleaned it up with thinner and gave it a transparent lacquer coat. Not a long lasting beauty but at least re doable.

Have fun

Sven

The current clear urethane products have much more durability than nitrocellulose lacquers and are solar resistant.

Back in early fifties the "Candy Apple Red" custom paint jobs had clear lacquer topcoats and they to be repainted before every show.

On the street they would last about 3 months before the red pigment (made from south american beetle wing covers) faded completely out.

Now all the present vehicles have lasting "Candy" finish options.

Lonnie

Been up late the last few evenings. I made some fabric patterns and cut out the fiberglass cloth to match.

You may want to skim coat the finished fiberglass with bondo to get a smooth base for painting without sanding into the fiberglass cloth.

Are you logging all your hours?

Lonnie

I really admire your work. When building canoes we use the fiberglass cloth "on the bias" when doing curved areas. Your wife will explain it to you ;^). Anyway it makes the cloth lie better and comply more closely with the curves. It also eliminates many of the "V" cuts you have to make when using the cloth along it's length.

Keep up the good work. Your posts are inspiring many of us.

I'm going to wet sand the body and add a clear coat of epoxy. It will have the wood finish. If I decide I don't like that, I'll paint it.

I'll probably be pushing 800 hours by the time I'm done.

Originally written by Wngnut on 8/27/2009 3:51 PM

I'm going to wet sand the body and add a clear coat of epoxy. It will have the wood finish. If I decide I don't like that, I'll paint it.

I'll probably be pushing 800 hours by the time I'm done.

At $100 per hour, that's around $8,000. Now we understand why a storebought sidecar is so expensive!

You will certainly be proud of it. I've been watching this thread since the start and you are quite a fabricator. Can you imagine asking someone else to do that level of work for you and trying to commnicate to another person to get it the way you want it? I don't think so! When you are finished, it will be uniquely yours. I hope you enjoy it. It's a terrific job.

I love that kind of work and do it all of the time myself. Apropos of nothing, here's a custom handle that I made for my new 6" Kurt vise on my new to me mill.

I wish the cloth was long enough to lay sideways. But it was a tad short:o( "Story of my life" :o) We got it though. The last side turned out great!!! I'm going to wet sand the body ( to get rid of a couple lumps that I have ) and roll a thinned epoxy onto it so it will be really shiny. I still have the bottom to do. It will be easy. This is a fun skill to learn. I have been gathering stuff up to build a reverse trike out of my KZ650. I'm going to make a hood to cover up some of the tubes and make it look interesting. I'm going to try a couple new things on that:o) It looks good in my head:o)

You say:

"It looks good in my head.".....

That reminds me to my work a lot. I make things up in my mind sometimes for several years. When finally I get green light from the costumer it is like moulding "Adam with clay", although often with way too tight budgets.

Those few times I get to the point to make things for myself it becomes in deed "self satisfying" and a real relavation. (a pond in our farm without any own dwell water filled the neighbourhood with toads and frogs where they had disappeared 25 years earlier). Often I have to be happy if I get my projects done in double the time and budget I estimated in the beginning.

Then the poking comments from the best of all wives seem like blows below the belt line. Typically: "If you would have got it from the shop in the first round it would have become cheaper and your back wouldn't be akeing"

In the end the only what counts is that you have done it with your own hands and brain according to your personnel ideas. And you see fast where to twink and squeeze for to improve unlike many so called "experts".

Continue, get qualified advice when needed and do not let you stop or discourage from anybody.

"Attitude makes the difference!"

May God bless you and lead your steps on the right path.

Sven Peter

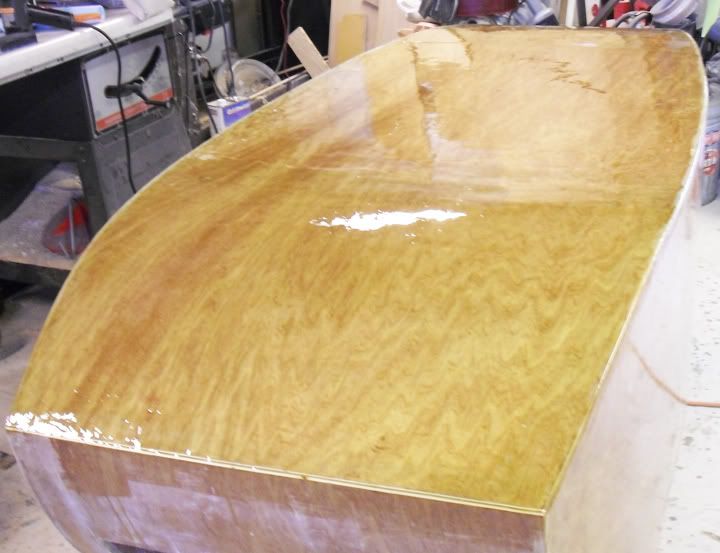

I took a couple of days off. But I'm back at it now 🙂 I glassed the bottom tonight. Tomorrow, I can start sanding things down for the sealer coat. It should look great then/ Then the body should be pretty much done. I still have to mount the windshield. But I don't see that taking too long?

Later, Wes

Bottom is Done!!!! I sanded it down and brushed on a seal coat. You can almost see the reflection from the road in it now 🙂

Tomorrow it will go back onto the saw horses and I'll sand the rest and seal it.

So close 🙂

- 29 Forums

- 11.9 K Topics

- 93.5 K Posts

- 4 Online

- 5,624 Members