The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

You definitely have too much time on your hands.

================================================

And WAY to much powder in the mortar, too much powder makes for a LOT of fire not distance 🙂 Great pic tho.

Kind of a disappointing evening. I finished cleaning up the new rear rim and masked it off for powder coating. The new powder went on perfect. I used a couple of those plastic deck boards in my oven to set the wheel on. Big mistake!!! One of them cought fire. It'll probably take three evenings to get the rim cleaned off again.

Originally written by Wngnut on 7/6/2009 7:17 PM

Kind of a disappointing evening. I finished cleaning up the new rear rim and masked it off for powder coating. The new powder went on perfect. I used a couple of those plastic deck boards in my oven to set the wheel on. Big mistake!!! One of them cought fire. It'll probably take three evenings to get the rim cleaned off again.

Hmm, I guess there was too much heat. I understand that powder coating takes around 350 deg. F. to work. I can see whay it caught fire.

Well the fire turned out to be blessing. I learned an important lesson. Aircraft stripper is my friend:o) I was explaining the fire to a Buddie at work and he rebuilds Honda Civics. He mentioned that I should try the stuff. About two coats took it down to bare metal. Yeah!!!

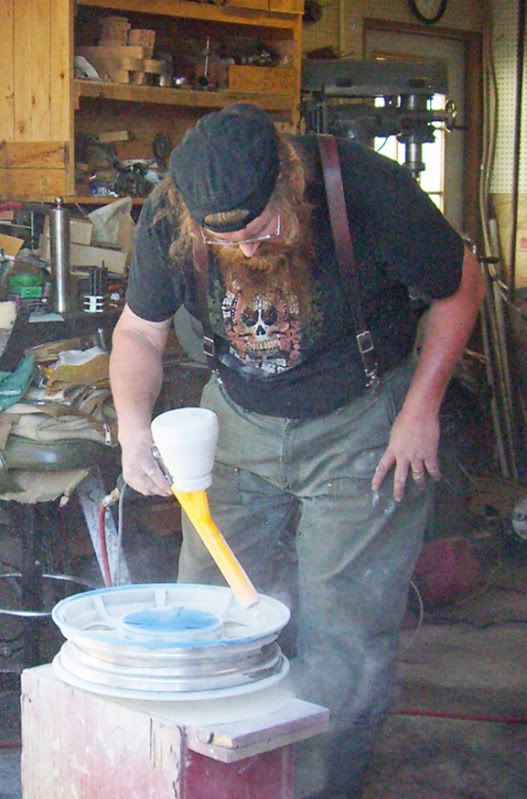

Here is the wheel ready to powdercoat the first time.

Here is an action shot:o)

The carnage:o(

Here it is now. I cant believe that it even took the original finish too. These could be used like this and look pretty cool.

I'll mask it off after work tomorrow and re coat it. I also have a new little shelf and a fire extinguisher for my shop:o)

Wes,,I hope the rubber cushions hold up to the 400 deg heat, I could be wrong but I think that this type of cushion isn't replaceable.

This stuff cures at 350 degrees. The fire was caused by the plastic blocks being to close to the burner. I have that problem solved. I'm sure the cushion will be fine.

Thanks

Well, my wheel turned out pretty Awesome!!!I'll get some pictures tomorrow. I'll also mount the new car tire:o) I have a coupe wheels to coat for another project that I'm going to do tomorrow also.

Come on Friday!!!

Hey Wes,

Where'd you get the powder coat gun? I saw one at Harbor Freight, but it's always hard to tell if their stuff's any good. For a lot of tools I don't care, if it last for the duration of a job the tools served the purpose and it's disposable. But for my core tools (day to day tools) I always try to buy the best I can afford. The powder coat gun wouldn't be used often, but it seems like one of those tools that it might pay to get a good one. But I might be wrong. Never tried powder coating before.

Hey look 10,000 hits :o)

My Gun is the harbor freight model. It works great for me. I'd stay away from their powder though. Get it off EBay. Much savings there.

Got a lot done today, but I don't have time to post pictures now. Sorry.

If your interested in a power coat gun check this out, Caswell sell good products.

http://www.caswellplating.com/powder/ez50.html?utm_source=MailingList&utm_medium=email&utm_content=tedandlila%40peoplepc.com&utm_campaign=EZ50

Here is the wheel I coated. It is a pearl White. I like it:)

My gun was bought on sale for $70. I've used it a lot and haven't really had any troubles with it. Just make sure you use a good air drier on your air line. I've even done a couple of paying jobs with it$$$ Most of my friends I'll spray and bake for free if they buy the powder and prepare the part. That way they Owe me:o)

I was working on my exhaust today and while one of the parts was cooling I decided to work on the new suspension. I had to take off all the chrome racks to remove the old rear shocks. I realized that I needed the racks on to fab up the new hangers. D'oh. Well, since the racks were off, I decided to scrub all the old road grime and rust off of them. Put on the new shocks. That out of the way, I reinstalled the racks. third time was the ticket!!! I can't believe that I forgot how it all went back on. Man it's hot today.....

Hot in Burley?

106 in Boise yesterday so we went up to Emmett where it was a cool 99.

No midday shop work going on here for a while. Early morning and hoot owl till it cools down.

Lonnie

- 29 Forums

- 11.9 K Topics

- 93.6 K Posts

- 4 Online

- 5,624 Members