The 2026 Sidecar Rally registration is now open! Click here: USCA 2026 Rally Registration Form

Wingnut, I really appreciate the effort you are putting into documenting your sidecar build. For those of us who have not attempted it (yet) it will provide a large body of valuable knowledge to reference. Enjoying the ability to watch the process.

Lonnie,

I still have the gussets to add. I have been waiting to see how things look with the body on. I am making them bigger than I originally planned. I might add a diagonal brace also? I haven't decided yet. Thanks for your input:o)

Wes

That diagonal brace sounds like a VERY good idea. I'm not a materials guy but I'm tending toward agreement with the opinion that your frame tubing seems to be a little on the light side. Claude and Stacey would be a good folks to consult on that.

Tonight I replaced the front motor mount with some grade 8 all thread. The original was a little short. It was kind of a bear to get out. But I got it. I also engineered a front gusset. This will hold the front upper mount.

I have been poring through my saved sidecar pictures and quite a few of them have frames that are made with tubing that looks very similar to mine. This first one is a Harley frame I think? It looks like there are only 4 - 3/8" U bolts that hold the entire car up?

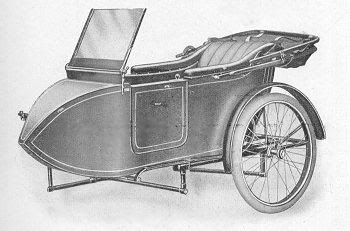

This second I think was a Watson? From the pictures the tubes in this frame look to be smaller? If I remember it was a fairly big car to?

I think when I get the gussets welded in place it will be really safe. They will keep the frame square. The center cross tube will act like a gusset to keep the axle from wanting to lean in, keeping the wheel parallel.

I really appreciate everyone's input here:o)

Thanks, Wes

Wes,

You can certainly do whatever is comfortable for you. The old Watsonian you showed was probably hooked up to a less than 20 BHP motorcycle. The stress we put on modern rigs is much more than the norm for the old days. I'm just suggesting that a diagonal brace is a good idea.

I've really enjoyed following your project and I wish I had your skills.

I've sold several sets of those U-bolts on eBay in the past few years. They are 7-16" on the threaded portion but they are forged and are extremely strong. Harley quit using the U-bolts around 1997 when they changed to the single leaf springs. Now they use a metal plate on top of the spring with four 7-16" bolts through the frame on each side.

Consistent with avoiding too much added weight, it pays to be on the strong side with sidecar frames. The tubing on an HD sidecar is 1-1/2" diameter heavy wall, at least 3/16" wall, IIRC. The cross bar is similar only 1-1/4" wall. The tubes are very strong and flexible.

You're doing a great job on your sidecar. The way you have it planned is very good. Time will tell if it's strong enough and more bracing could be added at any time.

I'm planing on 4 gussets. One in each corner. I'll probably weld them onto the top of the tubes so dirt won't collect there. If they were 6" X 12" X 1/8" steel. Would that be as good as a diagonal brace? I would think it might be a little stronger? There would be way more surfaces welded to help keep things straight. A diagonal brace would only have 2 points.

This is fun, isn't it:o)I like building things.

Originally written by Hack'n on 4/12/2009 8:49 PM

I think you might consider some frame reinforcing to keep from it racking and flexing.

Lonnie

Agreed 🙂

"This is fun, isn't it:o)I like building things."

Its pretty obvious to all of us that you like building things. I imagine that this project will never be done. I just hope you're not going to be disappointed when you the only thing left to do is ride it.

Every one here has been been enjoying your build. All the best of luck to you and watch out for all that machinery you are using,

all those tools have sharp teeth.

Originally written by Wngnut on 4/13/2009 10:54 PM

I'm planing on 4 gussets. One in each corner. I'll probably weld them onto the top of the tubes so dirt won't collect there. If they were 6" X 12" X 1/8" steel. Would that be as good as a diagonal brace? I would think it might be a little stronger? There would be way more surfaces welded to help keep things straight. A diagonal brace would only have 2 points.

This is fun, isn't it:o)I like building things.

Yes, it is a ton of fun and a lot of satisfaction comes during the build and then after it is on the road.

As far as racking etc goes I think the gussets will do okay for you there. However there is also bending forces that will be acting on the frame from side to side. Keep an eye on things when underway. You can always add additional tubing paralell with what you have now if required...kinda like what they used to call a space frame.

We use 1 3/4 x .120 wall on our frames which are not nearly as wide as yours. Sometimes we use 1 1/2" x .120 on smaller bikes. I think the Velorex frames are 1 1/4" or close to it.

Another reason for larger tubing is if you are creating any pinch block type, tube inside tube, connections. 1 1/2" material fits inside of 1 3/4" x .120 and due to the size it gives a lot on holding force when clamped down. I recently flipped one of our rigs totally upside down in a left turn and no settings of the setup changed.

Don't let any of this discourage you please. We are all excited about your build and appeciate you showing us the progress. Your work looks really good!!

I have the gussets nearly drawn up. I talked to my boss today. We use some steel called Domex. It's 3 times stronger than mild steel. I'll make all my gussets out of it:o)

Hope you weren't on board when you flipped her Claude. I'd hate for you to injure yourself.

Been watching the progress and as others have said, I am impressed with your workmanship and the progress of the project.

With regard to gussets, I will give you my 2 cents from an engineering perspective, gussets in the corner will give you additional rigidity, however all the stress is put the area directly at the gussets you are still depending on the strength of your tube to hold the twist and yaw of the frame. If you take an 1/8 x 3/4 strap and run it from near your front mount to near your outside corner you have transffered the majority of the stress into that strap which is now taking the load down its length not torsional. Think of it as an old wooden screen door with a turnbuckle from the top hinge to the outside bottom corner.

Thanks for taking the time to share your project with the group, I admire you ambition.

Fred

I've been thinking of something similar to that Fred. I'll probably end up doing that. I finished drawing my gussets tonight. Hopefully I can get them cut out tomorrow:o) I wish we had a water jet machine at work:o( I'll post pictures:o)

Wes

I pulled the body back off the frame tonight. I had a buddie come over and look at things. The only problem he could see wrong with my design is the tube that runs along the bike. The car's weight is behind the rear mount. This might let that tube flex or bend. I got to looking and a piece of one inch shaft will tap into the DOM tubing that I'm using. I am going to insert it into that tube.

Wes

- 29 Forums

- 11.8 K Topics

- 93.3 K Posts

- 4 Online

- 5,600 Members